10 Easy Facts About Insulated Spandrel Panel Detail Explained

Table of ContentsInsulated Panels Can Be Fun For AnyoneExcitement About Spandrel Panel Curtain WallEverything about Insulated Spandrel Panel DetailNot known Details About Spandrel Insulation How Nhbc Spandrel Panels can Save You Time, Stress, and Money.Get This Report on Insulated Spandrel Panel Detail

Periodically, there are issues associating with having way too much unrestrained daylight, in some cases described as glare. The challenge is to aim for the highest possible noticeable light transmittance (VT) as well as the most affordable solar heat gain coefficient (SHGC) while not avoiding the glass from being as well reflective when watched from both the exterior and also the interior, while regulating glow.The systems need to be entirely assembled in a factory and also shipped to the website for installment on the building. The systems are put on the floorings, bundled in dog crates, using the tower crane and also lowered right into place making use of a smaller sized crane or hoist possessed by the glazing specialist. The mullion measurements often tend to be a little larger than a stick system because of their open area as compared to television form of a conventional stick drape wall area.

Devices can be put together in a manufacturing facility while the structural frame of the structure is being created. Where stick systems need several steps to put up as well as secure the wall surface, unitized walls show up on the site totally put together allowing the floorings to be enclosed extra quickly. Unitized systems also call for much less space on site for layout thus providing an advantage for urban sites with space constraints.

Opaque Spandrel Panels Fundamentals Explained

Equipments whose connecting legs lock additionally compromise the capability of the system to fit motion. Some unitized layouts are sensitive to small irregularities in the spacing of adjacent components; for instance, if the module joints are slightly out of resistance, gaskets may not be effectively pressed and dampness protection may experience.

The four-way crossway describes the place where 4 adjacent devices satisfy. This is where area labor need to secure between adjacent units to achieve a climate tight wall. The interlocking legs of the horizontal mullions are one of the most critical user interface of a unitized system. Water that infiltrates the interlocking upright mullions drains to the interlocking horizontals that should accumulate as well as divert this water to the exterior.

How Spandrel Panel Curtain Wall can Save You Time, Stress, and Money.

These upstanding legs have gaskets that seal against the wall surfaces of the bottom straight. Some designs supply one honest leg that offers one line of defense versus air and water infiltration. Much more robust systems will provide 2 upstanding legs with gaskets on both legs. A splice plate or silicone blinking that is mounted on top of both surrounding devices as they are put up on the structure is commonly required.

The stack joint is the horizontal joint where systems from adjacent floors meet. Positioning the pile joint at the sill of article source the vision glass (usually 30" above the flooring) will minimize the dimension of the vertical mullions. This positioning makes use of the back span of the mullion over the anchoring factor at the slab to neutralize the deflection of the mullion below the slab.

Define that research laboratory tests are to be conducted at an AAMA Accredited Lab facility. Area Mock-up: For all curtain walls, stock or personalized, require building and construction as well as testing of an area mock-up agent of the wall/window setting up. This is best set up prior to the launch of shop drawings for home window production, so that there is a possibility to make layout adjustments based upon the test efficiency of the area mock-up.

The Single Strategy To Use For Spandrel Panel Curtain Wall

Area testing of drape wall surfaces: Require the field screening of drape walls for air infiltration and also water infiltration resistance, for high quality guarantee of curtain wall surface construction as well as installment. Need multiple examinations with the very first examination on preliminary setups and also later examinations at approximately 35%, 70% as well as at final conclusion to catch issues early and to verify ongoing workmanship top quality.

The details connected with this section of the BEDG on the WBDG were developed by committee as well as are planned exclusively as a way to show general design and building concepts only. Ideal usage as well as application of the ideas highlighted in these information will certainly differ based upon efficiency considerations and environmental conditions unique to each task as well as, for that reason, do not stand for the last viewpoint or referral of the writer of each section or the board members accountable for the growth of the WBDG.

Constant steel sill blinking at the base of the curtain wall surface secures the wall surface framing listed below from leakage through Bonuses the curtain wall surface. Sill blinking should have upturned end dams as well as totally sealed corners. Intermediate straight needs to be wept to the outside and also stop water from draining onto the head of the glazing system listed below.

The Best Strategy To Use For Spandrel Glass Panel

Spandrel glass adapters are used to decrease the depth of the glazing pocket to fit reduced profile of spandrel glass. Spandrel glass adapters ought to be totally bedded in sealant as well as integrated with polishing pocket edge seals to avoid water leak from polishing pocket to building interior. System measurement of breeding head and also sill extruded profiles permits defined flooring to flooring deflection at the stack joint.

Intermediate horizontals quit at the face of the vertical device jamb participants at each end. Devices are hung from the leading or face of the adjacent floor or building structure making use of mated brackets as well as field used bolts with a minimum of clearance for accessibility as well as assembly. All connections and also braces located within the systems shielded or main climate seal zones are secured with suitable sealer products during field installment.

The Buzz on Storefront Panels

non-heat-treated) or totally tempered glass to remain in location till it can be replaced. Whether heat-strengthened or totally tempered, heat-treated glass products are produced in a similar fashion as well as using the exact same processing equipment. The glass is heated up to around 650 C (1200 F), after that visit the site force-cooled to create surface and side compression.

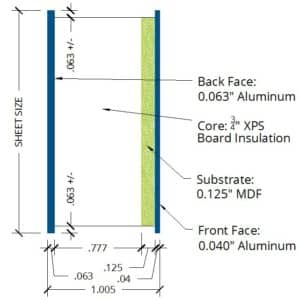

As suggested in Figure 1, insulation is usually used combined with spandrel glass. When the insulation is to be applied directly to the opacified surface area of the spandrel glass, it is important to collaborate with a glass spandrel maker, in addition to the glue and insulation providers, to guarantee these items work with the opacifying material - insulated spandrel panel detail.